Recently I had the truly amazing privilege to be a part of a culinary culture “bridge”, put together through Sammic, a worldwide manufacturer of commercial kitchen equipment and innovations. As Sammic says in their blog about the event, “A bridge is the nexus that links two paths, two worlds or two cultures; it is an element of communication that brings two distant or opposing points closer together”. In this case, they successfully built a bridge between the Basque culinary culture, American Chefs, and European manufacturing.

As the name of the program suggests, the goal is to form stronger relationships between industry partners. The participants of the program ranged from acclaimed chefs, powerhouse foodservice design consultants, to manufacturer representative professionals. Everyone involved is a culinary leader or trendsetter in the foodservice world. And here I was, soaking up everything I could under the warm Spanish sun, many times with a cool sweet Bodega K5 Txakolina (Spanish white wine) in my hand.

Sammic began the program with a tour of their factory headquarters in Azkoitia Spain, a small town of about 11 thousand people, located in the autonomous community of Basque Country. The first impression you have is how absolutely stunning the views are that surround the building. I’m more familiar with factories in the locations that are less desirable for residential building thus being a bit less attractive in nature. Location may not have the same impact on actual production as many other factors do, however, with Sammics average length of employment being 20 years, the retention rate sure does show how enjoyable it is to work here. The employees here have a lot of pride in the products they manufacture,

Sammic began the program with a tour of their factory headquarters in Azkoitia Spain, a small town of about 11 thousand people, located in the autonomous community of Basque Country. The first impression you have is how absolutely stunning the views are that surround the building. I’m more familiar with factories in the locations that are less desirable for residential building thus being a bit less attractive in nature. Location may not have the same impact on actual production as many other factors do, however, with Sammics average length of employment being 20 years, the retention rate sure does show how enjoyable it is to work here. The employees here have a lot of pride in the products they manufacture, and to ensure a high standard is kept up, the workforce is self-managed and has employee ownership. As the group strolled through the many areas of the building, showroom, R&D labs, production, engineering, and sales offices, it was very apparent that the culture of Basque Country lives strong at Sammic. The employees here are proud hard working professionals who find joy in providing quality equipment around the world.

and to ensure a high standard is kept up, the workforce is self-managed and has employee ownership. As the group strolled through the many areas of the building, showroom, R&D labs, production, engineering, and sales offices, it was very apparent that the culture of Basque Country lives strong at Sammic. The employees here are proud hard working professionals who find joy in providing quality equipment around the world.

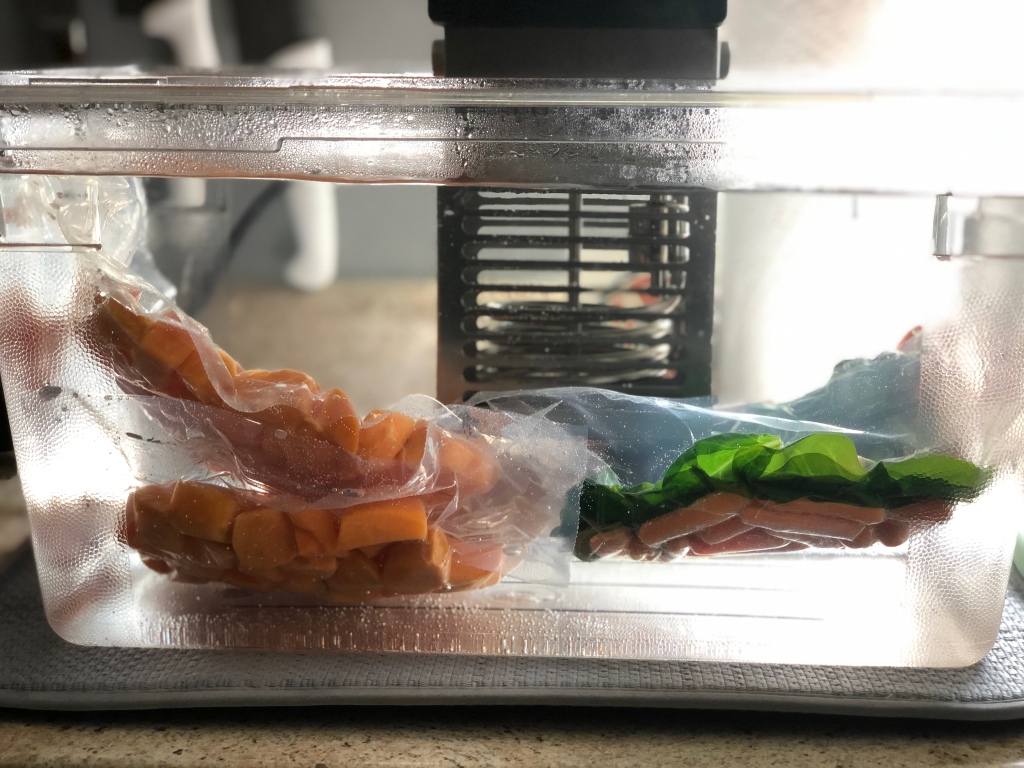

Once the formalities of the tour ended, the fun began. Chef Enrique Fleischmann heads up the culinary team at Sammic, he is the executive chef of two highly rated local restaurants and a leading culinary resource for Sous Vide cooking. Chef Fleischmann greeted the team in the culinary innovations center of the building. Sous Vide circulators, vacuum machines and an assortment of Sammic food preparation equipment was being operated by his team of professional chefs who are integrated with the development of new Sammic products. Their chefs engaged with demonstrations on sous vide techniques and gastronomic techniques. The food was incredible and the education was second to none. Many times, when cooking via Sous Vide, chefs become almost hyper-focused on a particular way of doing things. Enrique and his team showed a plethora of ways to accomplish refined menu ideas. As the demonstrations were winding down, Sammics management team presented the acclaimed chef’s, Josiah Citrin, Paul Kahan and Ilan Hall, a gift of custom engraved Smart Vide 8’s, the most top of the line Sous Vide calculators available. The circulators have Bluetooth HACCP tracking capability, remote wireless operations, precision probe capability, and the most durable stainless steel design on the market.

Now that the appetite has been peaked, it was time for lunch. The group was now shuttled through the beautiful Basque countryside to a Gastronomic Society in Azpeitia. The theme of sharing good food and enjoying time with family and friends is at the center of everything here in the Basque Country. A Gastronomic Society reminds me most of something between a midwest supper club, and a classic cigar club. A small kitchen and dining area are owned by a privet group of people, usually men, who share in cooking together and enjoying each others company. It’s almost like a Sunday dinner with the family but rather than just mom cooking, everyone is in the kitchen sharing in the experience. Since food is so important in this region, sharing it with guests is so very intimate of a process. As we sat down to a large table that was filled end to end with delicious bite-sized portions of food called Pintoxs, more commonly known as tapas in the states. This was the first time we all as a group of chefs, consultants and manufacturers had a chance to sit down and get to know each other. You could not dream of a better icebreaker than wine, fresh anchovy, and my new favorite food, tortilla.

A tortilla in Basque Country isn’t the same as you expect from the US, it’s actually a Spanish omelet. These omelets are most commonly made by softly cooking, almost boiling, onions and potatoes in oil until they are soft rather than fried. Once they are finished you remove them from the pan and remove most of the oil, leaving just enough to cook a load of beaten eggs and the potato and onion mixture. Again, cooking at a lower softer temperature unit the eggs begin to set. Once they have reached this point, about 5 minutes in, you flip the whole omelet over using a plate to cover the pan and slide the omelet back into the pan from that plate. Finish cooking for a few minutes and cut it into small shareable servings and you are ready to present your first pintxo!

A tortilla in Basque Country isn’t the same as you expect from the US, it’s actually a Spanish omelet. These omelets are most commonly made by softly cooking, almost boiling, onions and potatoes in oil until they are soft rather than fried. Once they are finished you remove them from the pan and remove most of the oil, leaving just enough to cook a load of beaten eggs and the potato and onion mixture. Again, cooking at a lower softer temperature unit the eggs begin to set. Once they have reached this point, about 5 minutes in, you flip the whole omelet over using a plate to cover the pan and slide the omelet back into the pan from that plate. Finish cooking for a few minutes and cut it into small shareable servings and you are ready to present your first pintxo!

The pintxo experience is one that will live with me forever, it is as welcoming of a way to eat than you will ever have. Just like our tortilla pintxo, these small servings are easy to pick up and eat, a common statement in Spain is “eat little bites, a lot!”. The restaurants and bars in this area all have pintxos out ready for people to enjoy. This is how it goes, you walk into a small three or four table place with a tiny bar, a few chairs, and are warmly greeted. You order a beer or wine for a couple of euro, more than likely unable to keep your eyes off of the plates of food displayed out over the bar. If a particular item looks good, you ask for one and they hand it over. Each is only a few bites so you can inexpensively taste so many great things while sipping your wine. The key and I can’t stress this enough to anyone new to pintxos, is to find the best of many places. You don’t need to spend all of your time in one place, get one or two pintxos and a glass of Txakolina and head next door to the next place. Meet and greet everyone you see and bathe in the loving culture of Spain.

After our long lunch and tours around the local area, filled with laughter, wine, and bite-sized local delicacies, it was time to get ready for dinner at the three Michelin star restaurant Martin Berasategui. By this point, our group has been tasting our way through Basque Country only to end up at one of the worlds top restaurants. In fact, only a few days later, it would be named No.76 on the Worlds Best List, ahead of the famed Perse, and French Laundry. What was even more special about the meal wasn’t that it luckily landed on my birthday, which it did, but the menu was The Great Tasting Menu 25 Year Anniversary featuring the best and most popular signature dishes of the last 25 years. 13 courses of incredible plates that pushed the boundaries on all of the senses followed by three incredible desserts to finish. The meal included some amazing personalized touches from the chef such as signed chef coats for our famed chef guests presented by Martin Berasategui himself and a special birthday dessert for me. An absolutely incredible culinary experience I will cherish for life.

After our long lunch and tours around the local area, filled with laughter, wine, and bite-sized local delicacies, it was time to get ready for dinner at the three Michelin star restaurant Martin Berasategui. By this point, our group has been tasting our way through Basque Country only to end up at one of the worlds top restaurants. In fact, only a few days later, it would be named No.76 on the Worlds Best List, ahead of the famed Perse, and French Laundry. What was even more special about the meal wasn’t that it luckily landed on my birthday, which it did, but the menu was The Great Tasting Menu 25 Year Anniversary featuring the best and most popular signature dishes of the last 25 years. 13 courses of incredible plates that pushed the boundaries on all of the senses followed by three incredible desserts to finish. The meal included some amazing personalized touches from the chef such as signed chef coats for our famed chef guests presented by Martin Berasategui himself and a special birthday dessert for me. An absolutely incredible culinary experience I will cherish for life.

The Kitchen Bridge Program was an extraordinary industry experience that helped build lasting partnerships and friendships while educating us on so many facets of the hospitality world. I thank Sammic for this experience and look forward to one day returning to Spain to enjoy some more of the culture!

Sammic began the program with a tour of their factory headquarters in

Sammic began the program with a tour of their factory headquarters in  and to ensure a high standard is kept up, the workforce is self-managed and has employee ownership. As the group strolled through the many areas of the building, showroom, R&D labs, production, engineering, and sales offices, it was very apparent that the culture of Basque Country lives strong at Sammic. The employees here are proud hard working professionals who find joy in providing quality equipment around the world.

and to ensure a high standard is kept up, the workforce is self-managed and has employee ownership. As the group strolled through the many areas of the building, showroom, R&D labs, production, engineering, and sales offices, it was very apparent that the culture of Basque Country lives strong at Sammic. The employees here are proud hard working professionals who find joy in providing quality equipment around the world.

A tortilla in Basque Country isn’t the same as you expect from the US, it’s actually a Spanish omelet. These omelets are most commonly made by softly cooking, almost boiling, onions and potatoes in oil until they are soft rather than fried. Once they are finished you remove them from the pan and remove most of the oil, leaving just enough to cook a load of beaten eggs and the potato and onion mixture. Again, cooking at a lower softer temperature unit the eggs begin to set. Once they have reached this point, about 5 minutes in, you flip the whole omelet over using a plate to cover the pan and slide the omelet back into the pan from that plate. Finish cooking for a few minutes and cut it into small shareable servings and you are ready to present your first

A tortilla in Basque Country isn’t the same as you expect from the US, it’s actually a Spanish omelet. These omelets are most commonly made by softly cooking, almost boiling, onions and potatoes in oil until they are soft rather than fried. Once they are finished you remove them from the pan and remove most of the oil, leaving just enough to cook a load of beaten eggs and the potato and onion mixture. Again, cooking at a lower softer temperature unit the eggs begin to set. Once they have reached this point, about 5 minutes in, you flip the whole omelet over using a plate to cover the pan and slide the omelet back into the pan from that plate. Finish cooking for a few minutes and cut it into small shareable servings and you are ready to present your first  After our long lunch and tours around the local area, filled with laughter, wine, and bite-sized local delicacies, it was time to get ready for dinner at the three Michelin star restaurant

After our long lunch and tours around the local area, filled with laughter, wine, and bite-sized local delicacies, it was time to get ready for dinner at the three Michelin star restaurant